With

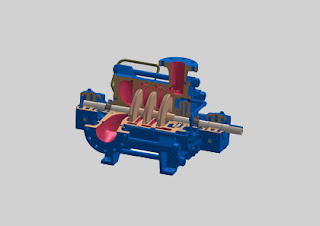

an increasing number of different industries, the need for a Centrifugal pump

is increase compared with before uses. This is because the Centrifugal pump is one of the most popular and suitable devices

for carrying fluids from one place to another. It is also one of the most

popular kinetic Pumps are used in chemical process industries. They are the

economy to use, easy to operate, and is ideal for maintenance.

The

Centrifugal pumps are important

device in your business venture. This device moves all liquid such as water,

through the mechanism of acceleration. This moves the water radically outwardly

to adjacent the cochlea. Liquid water moves through the pipe system. The pump

works in the theory of transformation of energy into kinetic energy. Captured

the eye of the impeller, the liquid rotates at a very high speed. Next, a

vacuum is created in the eye of the impeller; more water is optionally based on

the pump.

|

| centrifugal pumps |

The

barrel of the pump or Centrifugal pump

is mainly used for transferring any type of low viscosity liquid like water

under moderate pressure. As the mechanism of action is based on a spinning

wheel, movement of the liquid becomes easier. These pumps are made mainly in

water treatment plants, food processing plants and factories. If you want to

buy a Centrifugal pump for commercial establishments, it is better to take help

of a professional.

These

pumps are metals, ceramics, plastics, ranging from a wide range of materials

are available. The pumps are powered by an electric motor that comes with

high-end features. The pump is used today in the industry. One of the most

important features of this pump is self-priming. Unless it is filled with tap water,

it will not start operating. So you pump the water tank must be more than a

place.

Commercial

uses of these pumps are widely used as well as private properties. If you have

land, you fountain, garden, waterfall, and the other in the Centrifugal pumps can be used for

irrigation purposes. These pumps are also metal, ceramic, and are available in

a wide range of materials, such as plastic. You can use these drain pumps, mixing pumps,

industrial coolants, automotive Refrigerants, fire trucks, wind shields, jet

skiing, pumps, and other type of fluid can use these.

In

the internal properties, these pumps are used to pump daily use. Can lift water

from the ground is very easy and store water for future use. It is also

possible to use centrifugal force to improve the water in the pipes to the

desired level. It can quickly inflate any type of fluid through the device.

Yes,

but these devices are available in any market online these days. If you opt for

a set of standard pumps it can be used for agricultural and domestic purposes.

However, you should check the authenticity of the dealer. You can do this

through online reviews and comments posted by previous customers. Once you are

sure of the reliability of the manufacturers of rotary pumps, you can choose

one according to their availability.