|

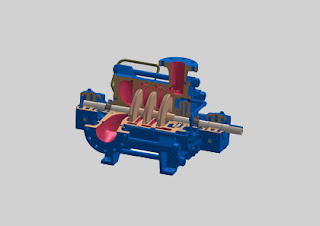

| Centrifugal Pump |

With the increase in the number of

different types of industries, the need for centrifugal pump has been increased manifold. This is because a

centrifugal pump is one of the most suitable devices to carry fluids from one

place to another. Moreover, it is one of the most popular kinetic pumps used in

industries for chemical process. They are very economical to use, operation is

easy and ideal for maintenance.

As far as the operations are concerned,

the amount of liquid or fluid that will pass through the centrifugal chemical

process pump and the other specifications are taken care of by the process

engineer. He is the person responsible for deciding about the property of the

liquid that will flow through, the density, pressure, viscosity, and above all

the flow rate. The flow rate will generally decide how much the capacity is of

the centrifugal pump.

|

| Centrifugal Pump |

Centrifugal pumps are generally made of inert or torpid materials. Since these

pumps are able to transfer liquids that are even highly corrosive, they are

extensively used in several industries dealing with chemical processing,

pharmaceuticals, electroplating, and effluent handling industries. Aside from

corrosive liquids, these pumps have also been extensively used for the transfer

of industrial wastes, suspensions, and sea water.

There are 2 ways to identify a good

centrifugal chemical process pump and that is no matter how much you subject

these devices to highly corrosive material, they will not wear out due to

friction. As a result, if it does not wear out easily, the depreciation will

also be less.